The core logging and sampling process which takes place in a specially equipped room complies with the world’s best practices and allows geologists to focus on the main goal – thorough study of core. We are proud to have extensive experience in designing and equipping modern core logging facilities to meet specific needs of any customer.

A well-equipped core logging facility used together with the AGR system makes the core logging process truly effective and accurate.

The facility is equipped using cutting-edge technologies to support the full core handling cycle – from geological documentation and core cutting to core storage racks.

- A minimum of specialists is required to move core boxes. Due to a highly ergonomic design of the workstation a geologist can perform the majority of operations (taking photographs, moving boxes) without any assistance.

- Wasting no time thawing the core. While geologists carry out logging of one batch, the next one is thawing in a designated area, along with heating the room.

- The conditions (from lighting to subject placement) are standardized so that all photographs look uniform and no post-processing is required.

- After logging is over, boxes can be easily moved further along the conveyor (to the next table, including the other room), where specialists can start cutting and sampling.

A core logging facility is equipped with convenient inclined roller tables of the in-house design, good lighting and modern materials. All technologies used have been tested and proven to be effective in our exploration projects.

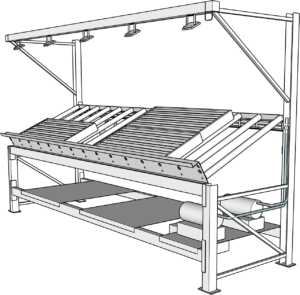

Core logging tables PLR2

The design is ideally suited for the core handling process. Rollers make it simple to move boxes along the table; height and angle are adjusted to ensure comfortable work; good lighting and an integrated photo booth allow geologists to see and record the geological structure as detailed as possible.

Today we are delighted to offer 2nd generation inclined roller tables with the following construction features:

- several tables can be joined in one line of a required length;

- height and angle are adjusted best to ensure comfortable work;

- up to 6 boxes of 5 meters of core can be placed on one section;

- boxes can be easily moved along the line;

- each table is equipped with water and compressed air hoses;

- compressed air blow gun and conveniently mounted spray nozzle allowing to reach any part of the table;

- each table has adjustable LED lighting along the entire line;

- there is a camera mount on each line;

- the angular core tray on the front plate can also be used to place oriented core.

The length of one section is either 2.25 m (the smaller model) or 3.3 m. Tables are optionally supplied with a small mobile table for a laptop and weighing scale, which can be moved along the entire line.

The length of one section is either 2.25 m (the smaller model) or 3.3 m. Tables are optionally supplied with a small mobile table for a laptop and weighing scale, which can be moved along the entire line.

Tables are easy to mount when moving from one deposit to another, as they are easy to assemble/disassemble in 3 hours.